Save time and money – with the new KC curtain-coat nozzle from SM Klebetechnik for contactless curtain coating

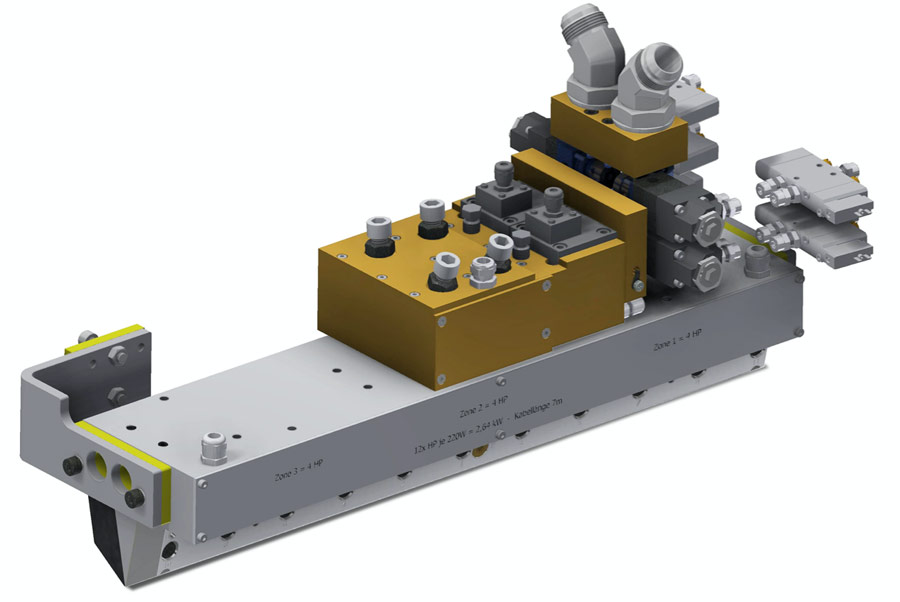

The KC curtain-coat nozzle is a reliable and user-friendly application head for contactless curtain coating developed by the experts and engineers at SM Klebetechnik that is designed to meet modern requirements in surface coating to optimum effect.

With its central control and material dosage system via the melter, it does not require any drive motors, switching modules, valve terminals or gear pumps. Consequently, acquisition costs are substantially lower and the application head requires significantly less maintenance.

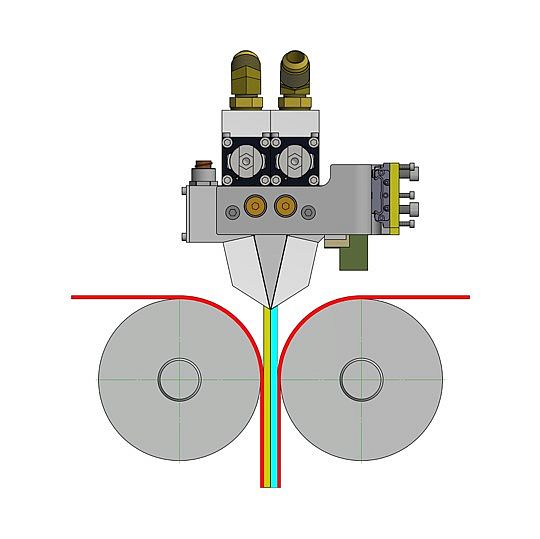

KC curtain-coat nozzle from SM-Klebetechnik for contactless curtain coating

Reproducible application results and processing temperatures of up to 220°C possible

The KC curtain-coat nozzle from SM Klebetechnik ensures consistent application via flow-optimised adhesive channels. Swappable mask plates facilitate flexible adjustment of the layer thickness and application width from 10 to 540 mm. The three separately adjustable heating zones allow processing temperatures of up to 220°C to be set.

A wide range of possible uses

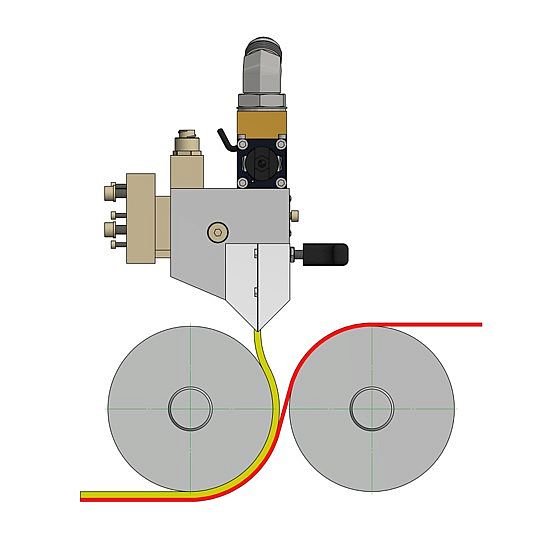

The possible uses of curtain-coat technology range from classic coating applications (e.g. coating a textile web) to sealing and the production of filter material:

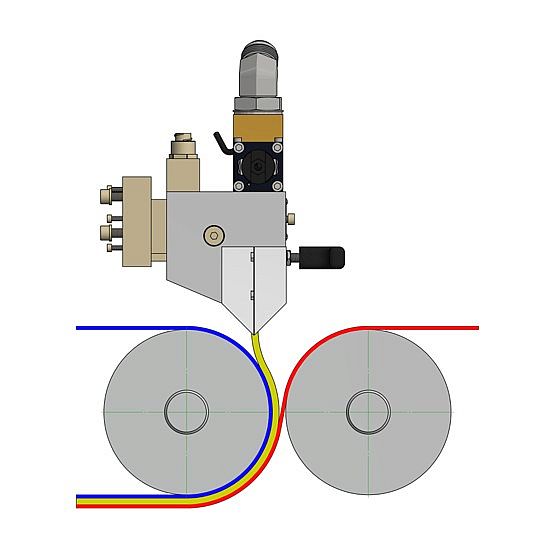

Application between carrier and release liner

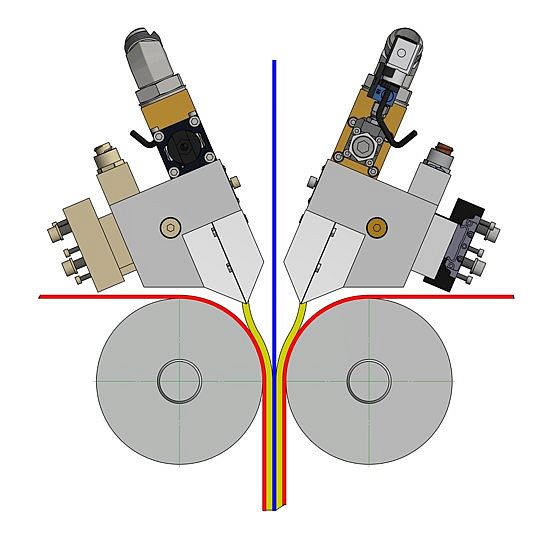

Dual-side application on release liners with two carrier films

Application on carrier film with release roller

CoEx application on two carrier films

We perform tests for you using your adhesives and sealants

Regardless of whether PSA, PU, PUR, bitumen or other materials are used, the KC curtain-coat nozzle from SM Klebetechnik reliably handles a wide variety of different adhesives and sealants in contactless curtain coating. At our in-house technical centre, you have the opportunity of testing the new application head in practice with your preferred adhesives or sealants.

Advantages of contactless curtain coating compared with contact coating

Would you like to learn more about or test the KC curtain-coat nozzle with your preferred adhesives or sealants? If so, call us on +49 (0) 24 52/91 72-0 or write to us at info@sm-klebetechnik.de – we’ll be happy to help you!

About SM Klebetechnik

Our machines for hot melt processing and coating tasks are used successfully in the automotive, mechanical engineering, graphic arts and adhesive tape industries, as well as in the furniture, construction, wood and textile industries. Our units are also integrated into production systems at adhesive and sealant manufacturers and compounders. In our certified, owner-managed company, over 70 employees are committed to the needs of our customers every day.