A focus on innovations, exchanges and development

TechDays 2024: A look back at the highlights of our in-house exhibition

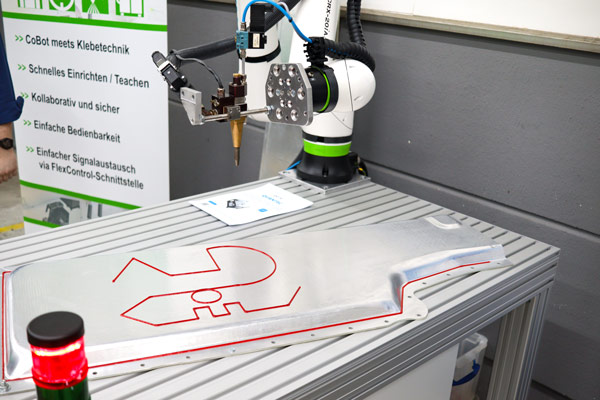

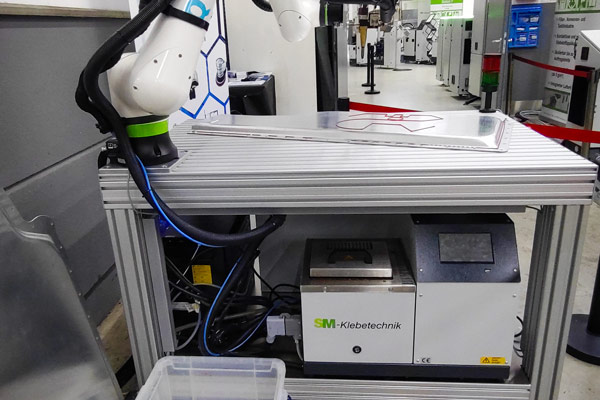

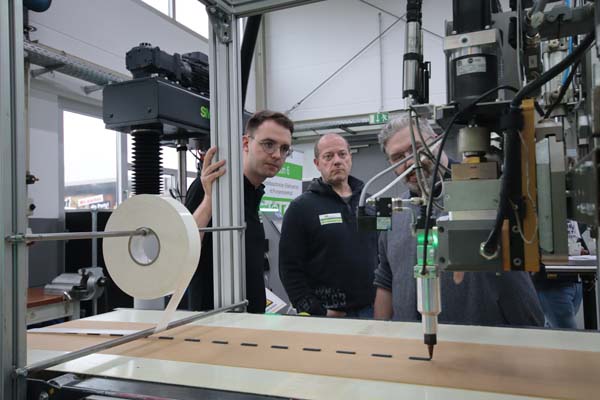

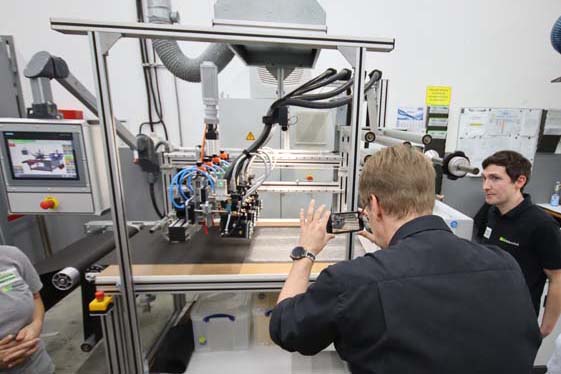

“Bonding – Sealing – Excitement”: Our “TechDays 2024”, which we held on Wednesday the 13th and Thursday the 14th of March 2024 in Heinsberg, were a real hit. Over 200 visitors attended the exhibition over the two days to see SM Klebetechnik’s wide range of systems, equipment and machines in use.

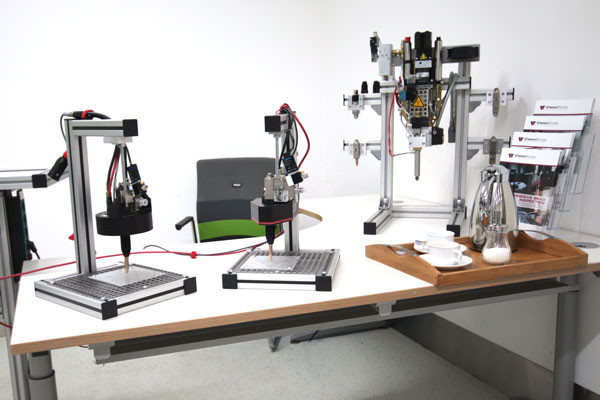

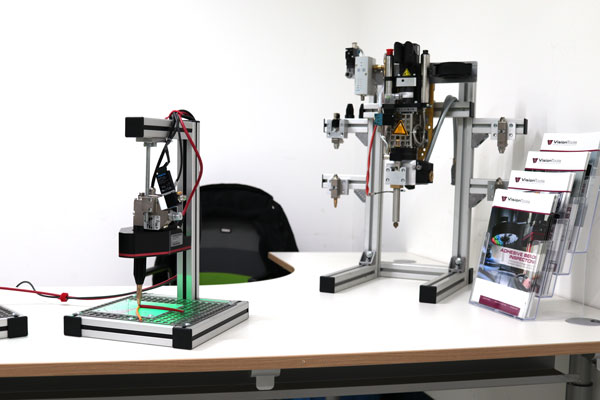

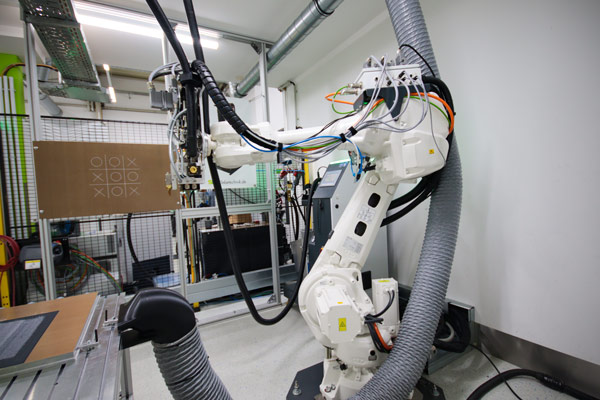

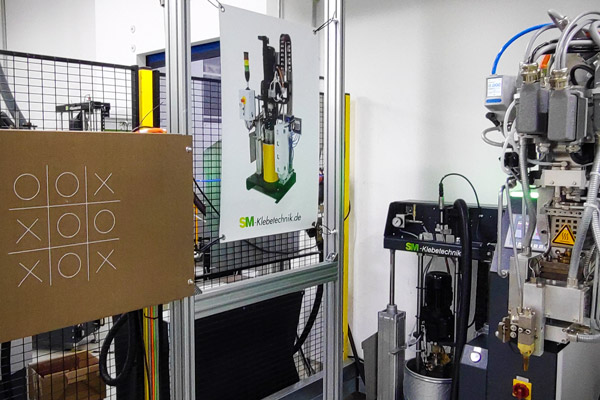

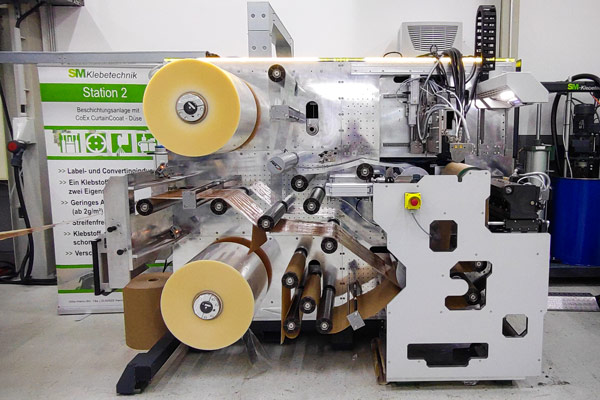

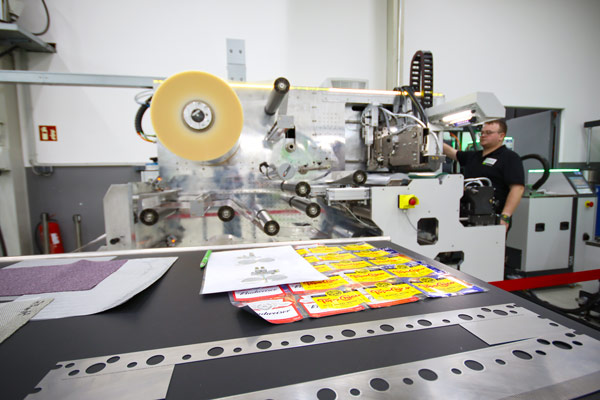

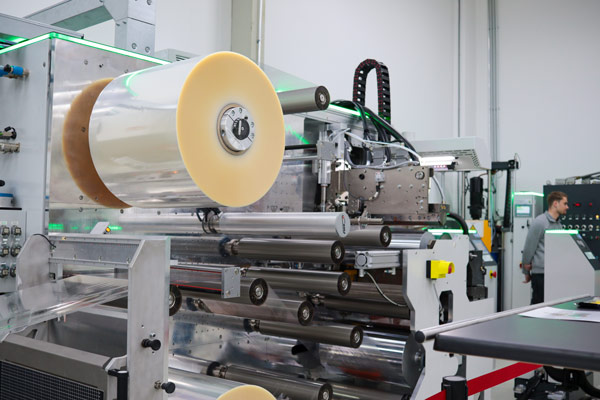

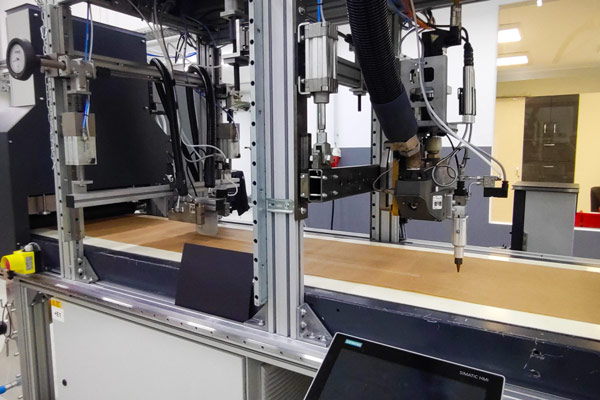

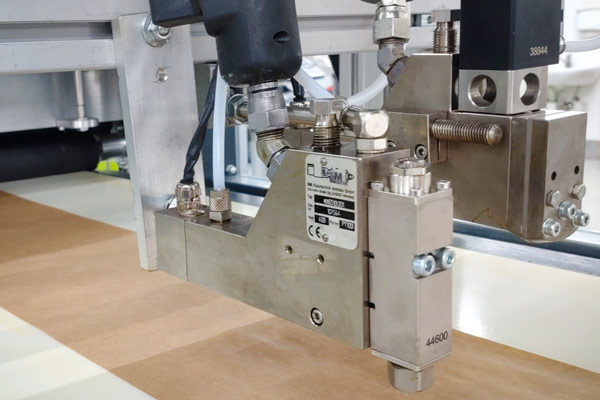

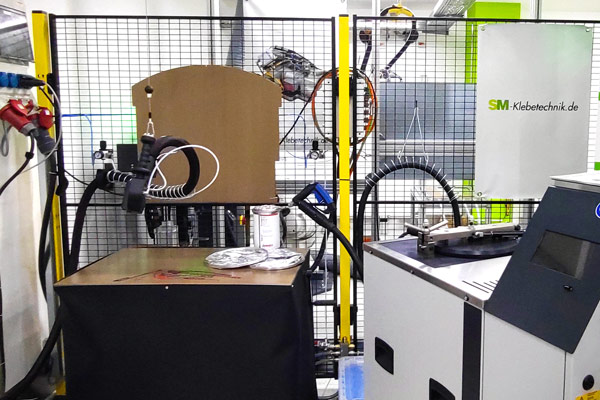

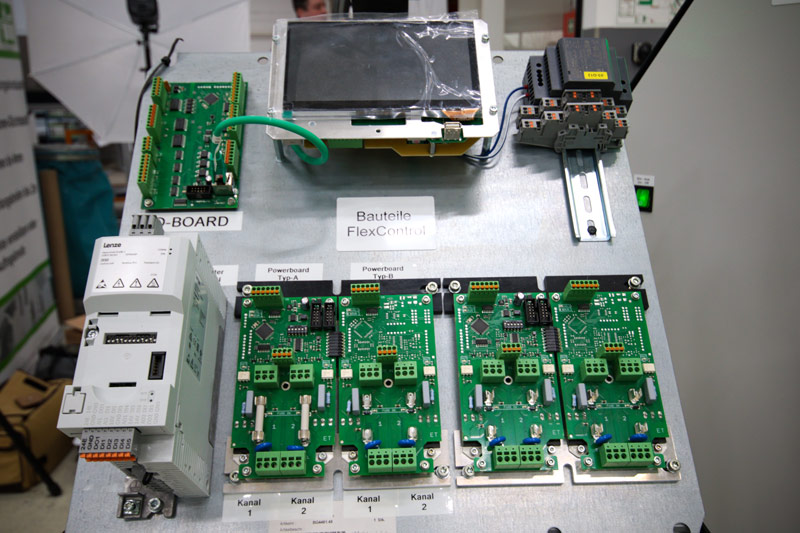

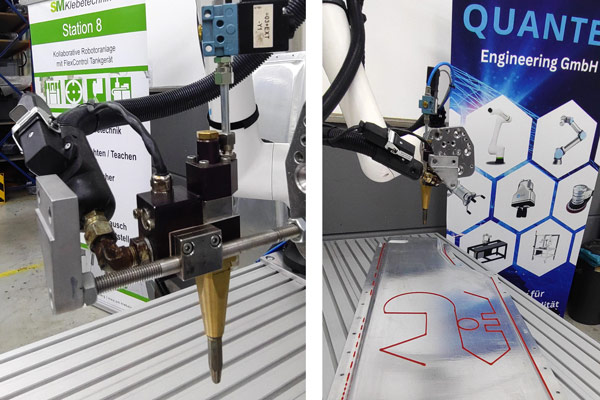

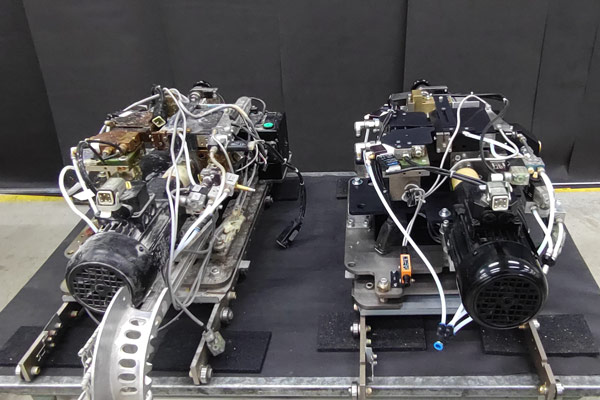

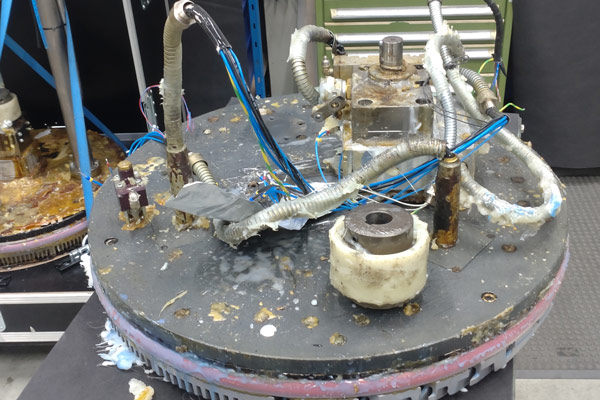

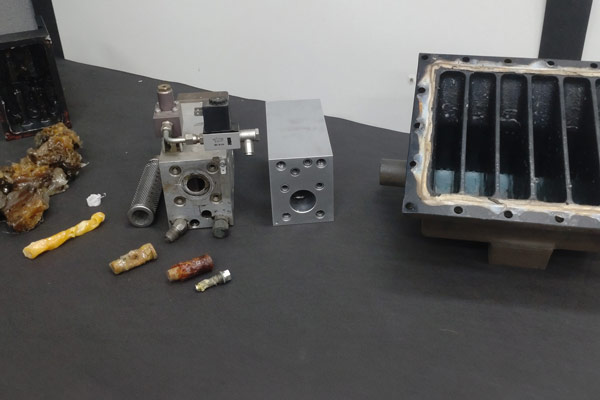

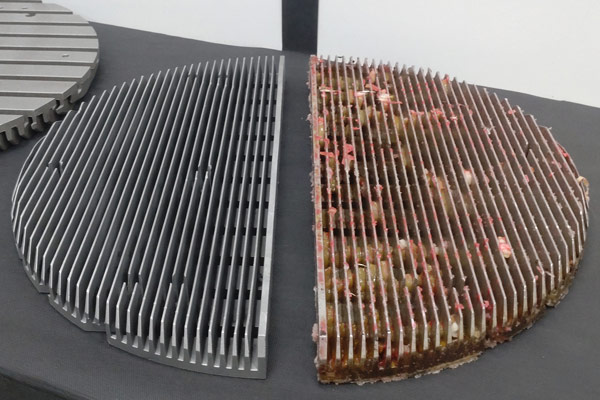

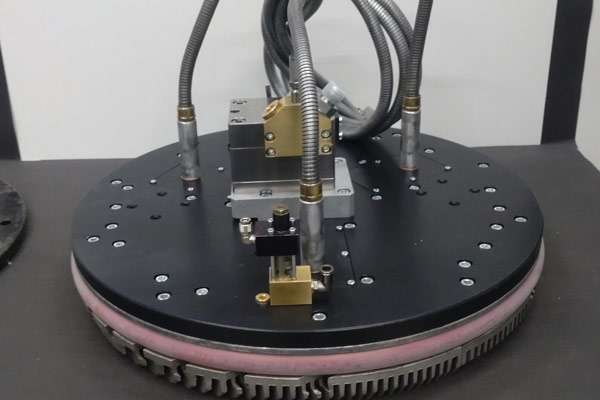

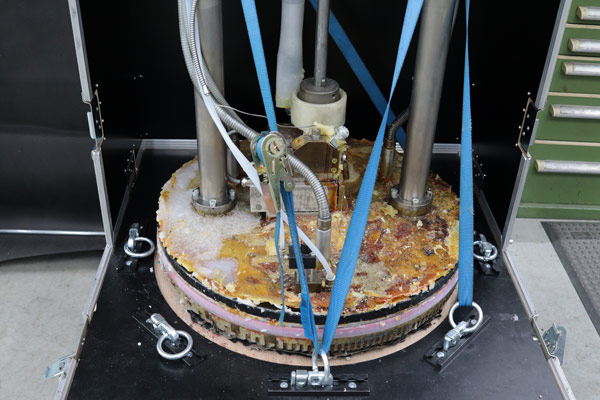

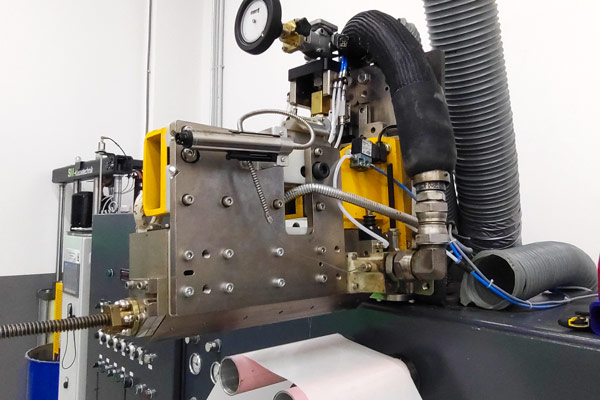

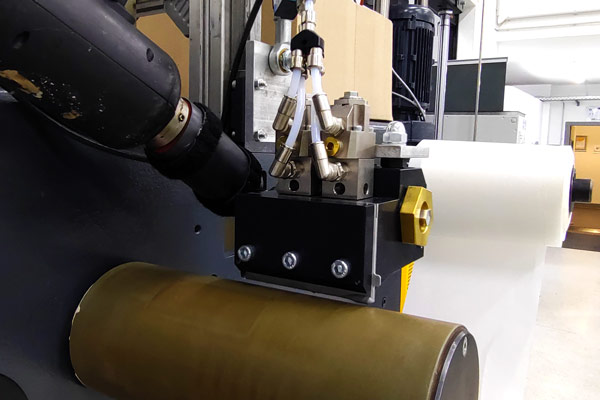

Amidst the lively atmosphere of the in-house exhibition, our employees gave visitors demonstrations of the innovative systems and equipment from SM Klebetechnik at different product stations:

Fascinating insight into our research and development department

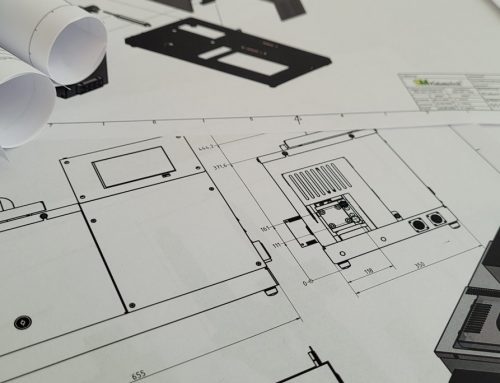

Attendees that were visiting us in Heinsberg for the first time were impressed by the exhibition space, our 500m2 Research and Development Technical Centre. In our Technical and Development Department, which is equipped with all the latest technology, our engineers test and simulate new special solutions using materials provided by customers and a range of methods that allow us to best meet their individual process requirements.

Networking and exchanging experiences – sharing knowledge, encouraging development

For all of us here at SM Klebetechnik, “TechDays 2024” was more than just an opportunity to present our systems, it was also a forum for communication, progress and development. “The personal exchanges and interesting discussions we saw showed just how closely our success is linked to our customers,” says René Schog, Managing Director of SM Klebetechnik. “We would really like to thank everyone that attended our in-house exhibition and for sharing their experiences and feedback with us. This will help us to come up with new solutions and developments in adhesive technology.”

Feedback from our visitors:

As an adhesive manufacturer / formulator, it was really interesting to be able to see our customers’ / end users’ different applications live. Perhaps next time you could provide more information for those of us that formulate mixtures.

It was a fantastic event. Great team, great products. I’ll be back.

A very welcoming atmosphere, I will definitely be back (possibly for SM Coating)

I don’t think that the event can be improved upon at all and I thought that the whole event was a real success.

A very professional event. No improvements needed.

The event was really well organised! We had a great day!

A massive thank you, it was all really well organised.

Interested?

Give us a call at +49 (0) 24 52 / 91 72-0 or send us an email to info@sm-klebetechnik.de – we will be happy to help you!

About SM Klebetechnik

Our machines for hot melt processing and coating tasks are used successfully in the automotive, mechanical engineering, graphic arts and adhesive tape industries, as well as in the furniture, construction, wood and textile industries. Our units are also integrated into production systems at adhesive and sealant manufacturers and compounders. In our certified, owner-managed company, over 70 employees are committed to the needs of our customers every day.