Special machine technology for bitumen processing

Special machine technology for bitumen processing

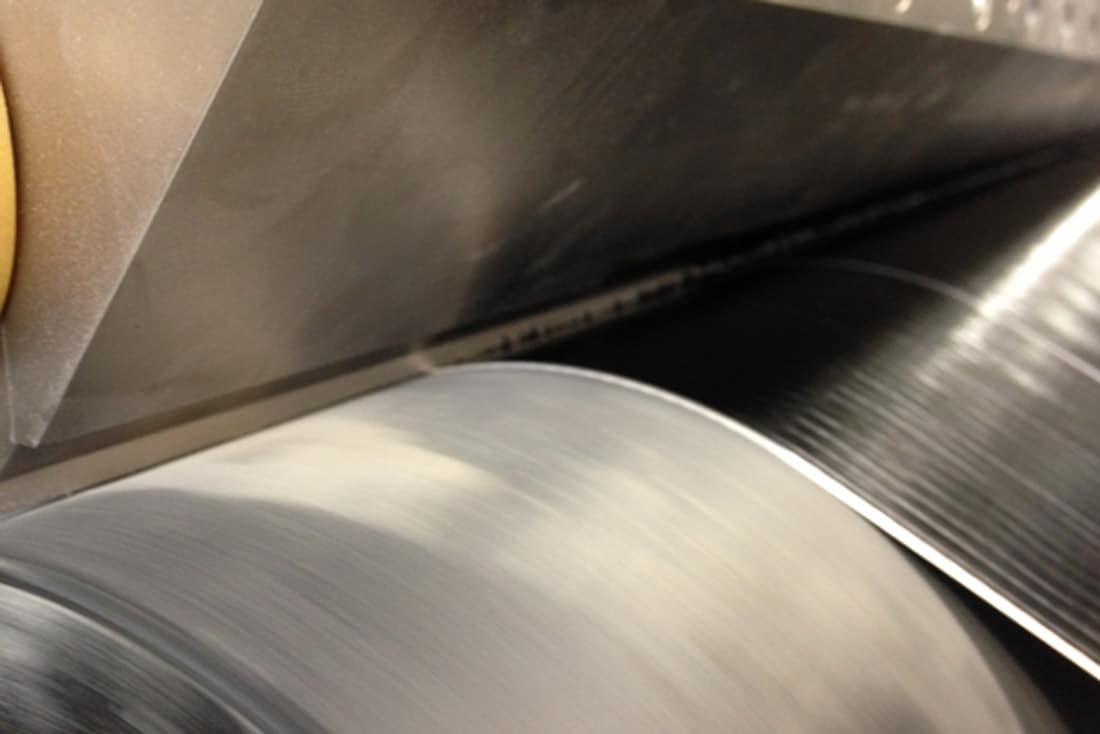

Processing of elasto-viscous bitumen masses places high demands on machinery and system technology. As an internationally leading producer of hot-melt adhesive application systems and an innovative special-purpose engineering company, we possess many years of experience and the necessary expertise in processing and coating films and similar material carriers with bitumen masses.

Feel free to contact us at any time!

Feel free to contact us at any time!

SM Klebetechnik Vertriebs GmbH

Otto-Hahn-Str. 19a

D-52525 Heinsberg

Phone +49 (0) 24 52 / 91 72-0

Email: info@sm-klebetechnik.de

VISION BECOMES

REALITY

VISION BECOMES

REALITY

Expertise, passion and free thinking

create the best solutions: from individual

bespoke systems to custom-fit modules.

Equipment and plant engineering for bitumen coating

Equipment and plant engineering for bitumen coating

What we offer for the professional production of single or double-sided bitumen sheets, polymer bitumen membranes, bitumen sealing strips, screed membranes and various types of roofing felt:

Bitumen processing in construction

Bitumen processing in construction

Bitumen products have proven to be excellent for sealing and soundproofing in the roofing and construction industry, especially for flat roofs, as well as in road construction. Bitumen masses, also known as ground pitch, are impermeable to water but require special measures during processing to preserve their unique properties.

Manufacturers of bitumen products such as bitumen sheeting or sealing tape, face the demanding task of keeping the thermoplastic bitumen processable at high temperatures on the one hand and ensuring precise, even coating of the base material on the other. SM Coating GmbH’s special coating systems ensure the reproducible application of bitumen and meet the desired requirements.

Upgrade to bitumen processing with SM Coating

Upgrade to bitumen processing with SM Coating

Manufacturers active in film or textile coating can benefit from cost-efficient conversion and product optimisation by using bitumen processing as a means of diversifying their products in the market. Existing coating systems can often be converted or expanded for bitumen processing.

Our experienced engineers at SM Klebetechnik and SM Coating will support you from the planning phase to the conversion of existing systems to bitumen processing as well as the development of new fully integrated systems. At our technical centre with a floor area of more than 400 m², we develop innovative solutions for you and carry out relevant individual testing to simulate the subsequent production process.

Experience and competence in bitumen processing

Experience and competence in bitumen processing

Conversion or renewal of existing plant equipment!

We would be pleased to advise you individually. We plan potential modifications to your existing coating system with the user in mind and in terms of technology and efficiency so that it meets the latest requirements for bitumen processing.

Replacement of a full existing plant for bitumen processing!

We offer you a comprehensive integrated package, from product development and planning, design and individual production at our factory, including software development and the integration of interfaces, to final assembly at your site by our specially trained technicians.

Replacement and renewal of individual components in an existing bitumen processing system

We engineer the necessary modules and assemblies in accordance with your wishes, taking into account all the necessary interfaces. Using retrofit kits, we swiftly modernise your system.

Added value through quality and swift service!

Even after the system has been installed, we perform maintenance activities. We offer you individual maintenance contracts. The members of our technical team are at your site quickly to provide support in the event of any disruptions.

15 July 2020

State-of-the-art hotmelt coating systems for bitumen processing

State-of-the-art hotmelt coating systems for bitumen processing

Greater efficiency in bitumen application thanks to slot nozzle technology

Thermal challenges and optimum coating are not just required in hot melt processing. SM Klebetechnik has transferred the advantages of hotmelt coating to the application of bitumen mass. The result is greater product variety and diversity as well as improved efficiency and savings for the customer (…)

Competence in bitumen processing – we are there for you!

Competence in bitumen processing – we are there for you!