Butyl system from SM Klebetechnik – efficient, productivity-enhancing and reliable

Butyl application: efficient application of high-viscosity materials up to 10,000 Pa·s – made possible thanks to SM Klebetechnik’s innovative system technology

Whether in the automotive or the construction industry, material viscosities of up to 10,000 Pa·s are not uncommon with hot-processable butyl sealants. With their above-average melting and delivery capabilities for butyl sealants at high material viscosities, SM Klebetechnik’s performance-optimised drum melters are currently being successfully used by many customers. The new systems are reliable, easy to maintain and offer market-leading melting and delivery capabilities for butyl application. In addition, the systems are designed to handle temperatures of up to 200°C.

Uses of high-viscosity materials and compounds

High-viscosity materials such as butyl or butyl rubber compounds are used, for example, in the automotive industry for sealing battery lids, battery housings (e-mobility) and bipolar plate stacks for fuel cells as well as for sealing components such as headlight gaskets, car bodies and windows.

In the construction industry, high-viscosity materials are used to produce sealing membranes for roofs, sealing adhesive tapes for interior and exterior areas (joint sealing tapes for masonry) and sleeves for ventilation and window connection tapes.

As well as this, individual profile seals (e.g. round cords, flat seals, etc.) and rubber sealing profiles with inserted butyl bead are produced using butyl or butyl rubber compounds, which are used in construction machinery, for example. Butyl is also used as a vibration damper between components, for assembling multi-pane insulating glass and for filling and transferring in cartridge containers.

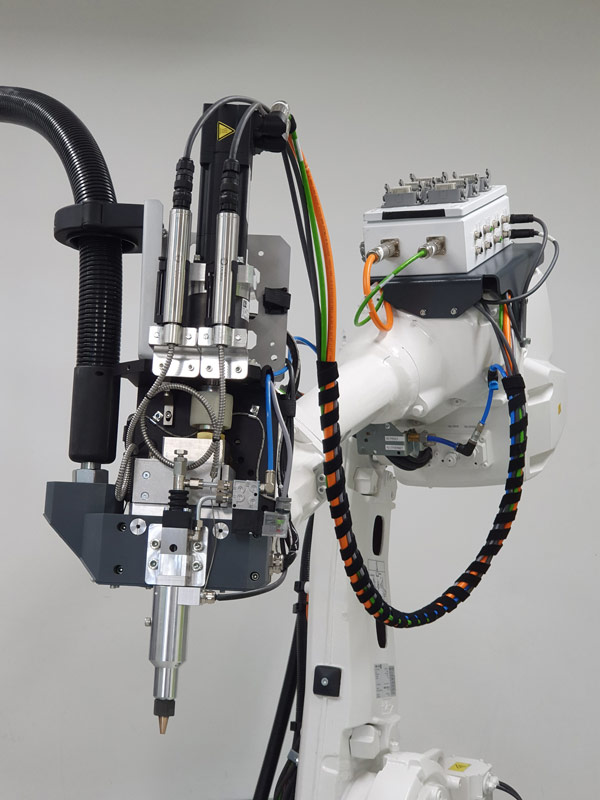

The new-generation butyl processing systems –

high processing temperatures, top melting and delivery capabilities

The engineers at SM Klebetechnik have developed a new generation of drum melters for the high-pressure application of butyl with the aim of making the processing of high-viscosity sealants more user-friendly and efficient. In addition to their proven reliability and ease of maintenance, they offer market-leading melting and delivery capabilities as well as the highest possible processing temperatures. The new-generation SM Klebetechnik butyl processing systems offer the following advantages:

What this means for you is that you can boost the productivity of your processes thanks to the high melt rate and the possibility of continuous delivery and application – without sacrificing operating convenience or system reliability.

Revolutionise your production with our butyl system and benefit from the high punch force, consistent melting performance, maintenance-friendly technology and individual customisation on the basis of your needs. See for yourself the benefits we offer and arrange a melting test with your own materials at our in-house technical centre.

Have we aroused your interest?

Call us on +49 (0) 24 52/91 72-0 or write to us at info@sm-klebetechnik.de – we’ll be happy to help you!

About SM Klebetechnik

Our machines for hot melt processing and coating tasks are used successfully in the automotive, mechanical engineering, graphic arts and adhesive tape industries, as well as in the furniture, construction, wood and textile industries. Our units are also integrated into production systems at adhesive and sealant manufacturers and compounders. In our certified, owner-managed company, over 70 employees are committed to the needs of our customers every day.