SM adhesive technology for producing environmentally friendly butyl tapes

Low maintenance, flexibly adaptable and efficient in consumption and application

Butyl tapes are coated sealing tapes that are highly versatile in the construction sector, such as metal, automotive, road and shipbuilding. The production of butyl tapes requires modern coating and adhesive technology. SM Klebetechnikoffers single components as well as complete coating lines for efficient butyl tape production

Depending on the application, the butyl tapes need not only to be adhesive on one or both sides, but also laminated with various materials. Butyl tapes are often used for sealing joints (e.g., between concrete slabs, roofing felt or window frames), for overlap sealing and fixing of assembly parts with corrosion and damp protection. The odourless, solvent-free sealing tapes are weatherproof and resistant to shrinking and are characterized by long durability.

The requirements of the finished butyl tape for permanently sealing joints and edges vary greatly depending on the application – from tough and hard to very soft, and from highly adhesive to less adhesive. For this reason, modern, flexible, scalable application systems are necessary for economical production and butyl processing.

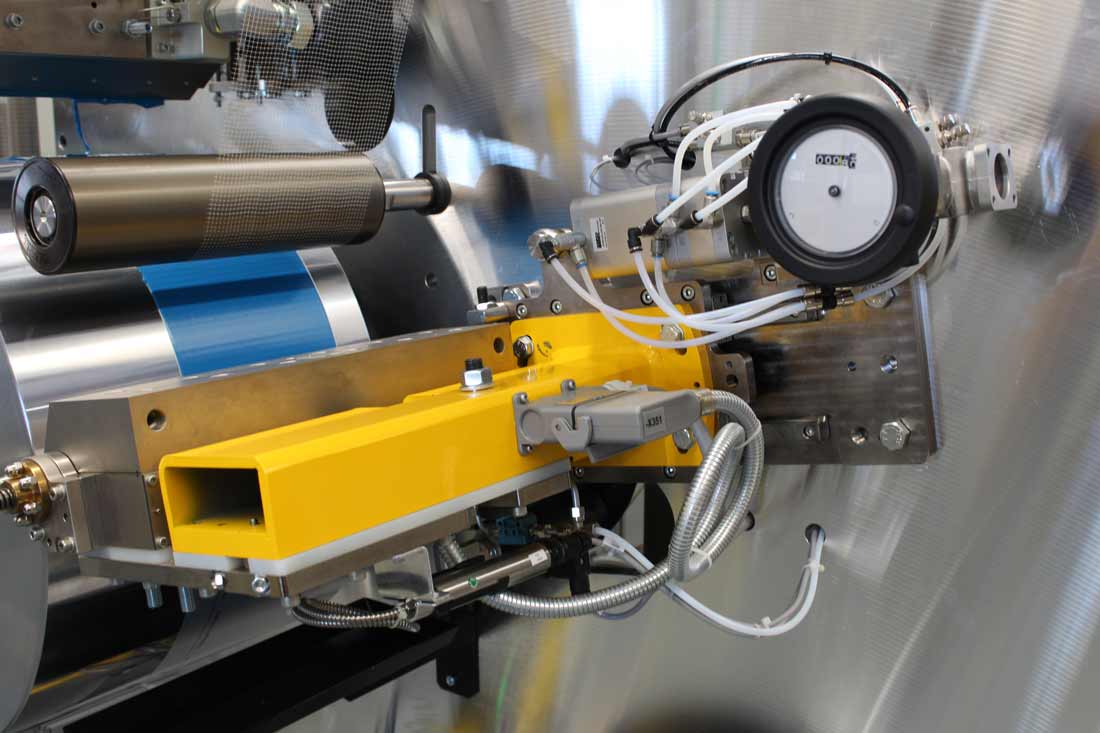

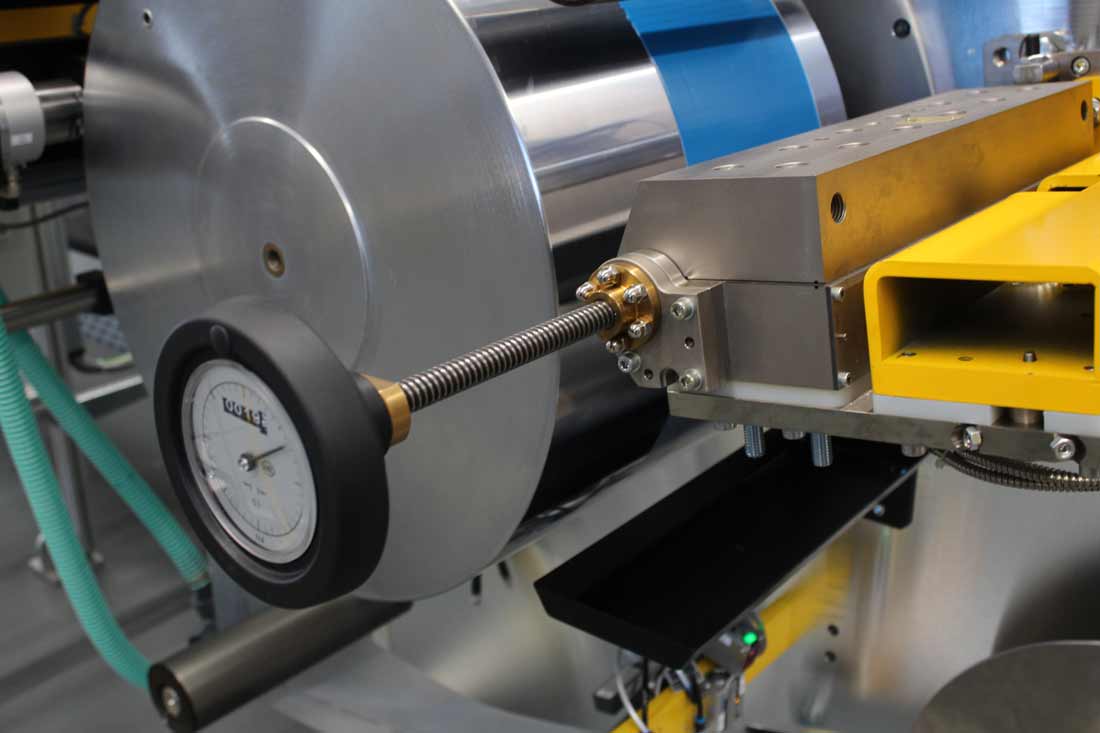

Leap in efficiency – wide slot nozzles for flexible butyl processing

Modular wide slot nozzle technology enables the production of ready-to-use butyl tapes in standard and special sizes with variable adjustable coating width and edge-to-edge coating. The coating thickness can be precisely controlled between 0.6 and 2.0 mm. Depending on the production requirements, the application temperature and quantity can easily be adapted to the process and also adjusted inline where required. “Butyl is solvent-free and therefore more environmentally friendly than other adhesives. At the same time, its properties do not change over years. That’s why butyl tapes are so widely used. With our reliable wide slot nozzle technology and the numerous lamination options, we enable our customers in covering a wide range of production,” explains René Schog, Managing Director of SM Klebetechnik.

Laminated butyl tapes for permanent sealing

Due to laminating butyl tapes with various backing materials, they are popular in construction and many different industries. Coating with aluminium, non-woven materials, EPDM, polyester, fleece or paper is possible. Butyl trilaminates or semi-finished products for further processing by your customers can also be produced with the coating systems from SM Klebetechnik. In order to prevent the adhesive bonding compounds from coming into contact with each other (e.g., while winding the adhesive tapes), a Releaseliner cover with suitable separation materials can be integrated in the production process.

Maintenance, converting production or new production line for butyl processing?

The individual case decides. SM Klebetechnik works with you to develop the appropriate, low-maintenance line concept for producing ready-to-use butyl tapes. This includes the modernisation of existing lines as well as the planning and implementation of new coating lines. Upon request, SM Klebetechnik can supply you with everything from a single source.

Conversion to drum melters and maintenance with individual components

You can replace defective or inefficient components with individual components from SM Klebetechnik as part of the retrofit modernisation. In particular, filling your system via drum melters or extruders brings a significant increase in efficiency. In particular, the conversion from butyl blocks to drum melters with strong melting performance and high flow rates for filling the coating line leads, in practice, to easier handling and noticeable cost savings.

Converting production to butyl processing

It is impossible to imagine many industries without sealing tapes. As they do not change their plastic characteristics over the years, are easy to process and more environmentally friendly than other materials, the market for butyl tapes is large. If you are planning to convert your production to butyl tapes, SM Klebetechnik is happy to support you. We will advise you on which changes are necessary to the existing line and will convert your production to an efficient manufacturing of high-quality sealing tapes using standard components, modern application technology and, where required, custom-made individual modules.

Plant engineering with the latest wide slot nozzle technology

The experienced engineers at SM Klebetechnik will work with you to develop your new coating system, tailored precisely to your requirements. To clarify complex processing issues, e.g., laminating with different materials, we can conduct individual test series in our technical centre to find the right solution for your production process. We handle every detail from planning to commissioning.

About SM-Klebetechnik

For more than 30 years, SM Klebetechnik has made a name for itself internationally in the development and construction of special machines and standard devices for processing adhesives and sealants.

Our machines for hot glue application and coating tasks are primarily and widely used in the automotive, mechanical engineering, graphic industry, adhesive tapes as well as in the furniture, construction, wood and textile industries. Our aggregates are also integrated in production plants at adhesive and sealant producers and compounders. In our certified, owner-managed company, over 60 employees work in the interests of our clients every day.