Filter bonding and filter construction

Filter bonding and filter construction – customised system solutions for the filter industry

Pressure, temperature and chemicals subject filter systems to high stresses. That’s why reliable adhesive bonds must meet high quality specifications, both in the production of filter material and in the filter bonding. To address these specifications SM Klebetechnik’s experts offer straightforward, low-maintenance, reasonably priced systems especially designed for processing adhesives and sealants. The individual filter bonding solutions improve filter production efficiency as well as filter function.

Filter construction: Material pre-processing systems

A variety of filter media are used in modern filter production. They include non-woven materials, paper or materials made of nanofibres. We at SM Klebetechnik offer high-performance systems and equipment for the precise bonding of these media:

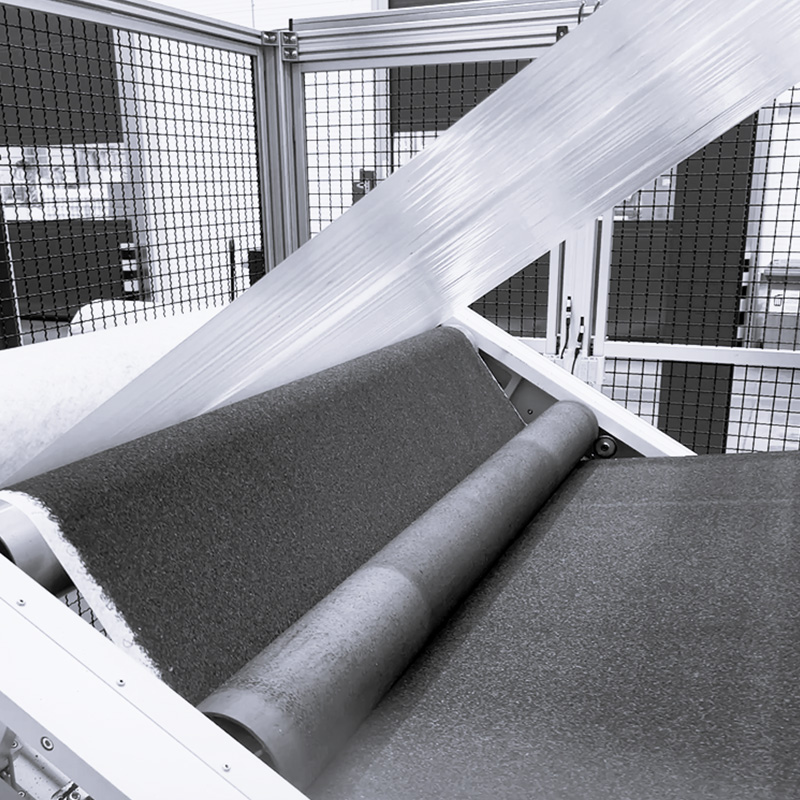

Non-woven coating with hot melt using the spray method with angle-fibre spray heads for bonding filter media

When coating non-wovens, the spray method can be used to apply reactive adhesives such a PUR or POR, creating a homogeneous, open-pored application pattern. The non-contact spray application in the adhesive process subjects application nozzles to less wear because it keeps them from getting plugged up with non-woven material or other particles.

The enhanced third-generation angle-spray heads enable a maximum amount of filter media (e.g. activated carbon or ion exchange resin) to be bound in a ratio of approximately 1:10 with minimal adhesive consumption. The surface spray application thus optimises the permeability properties of the filter media. Approximately 160 g/m² of filter media can be bound per pass through a station, whereby multiple stations or multiple passes enable a multiple of this figure. Production speeds of 15 – 25 m/min and widths of 0.8 – 2m are usual.

Using the same application technique, a covering fleece can be laminated in the final production step, thereby completing the composite.

Working in cooperation with SM Coating, we are able to replace and integrate the hot melt system of an existing system or, as a general contractor, develop, produce and commission a complete system worldwide from a single source in accordance with customer specifications. This includes the integration and full automation of all external components required (e.g. big bag station, powder spreader).

Using the customer’s requirements as a basis, we work together to develop the system concept, with a focus on:

Coating level in protective enclosure

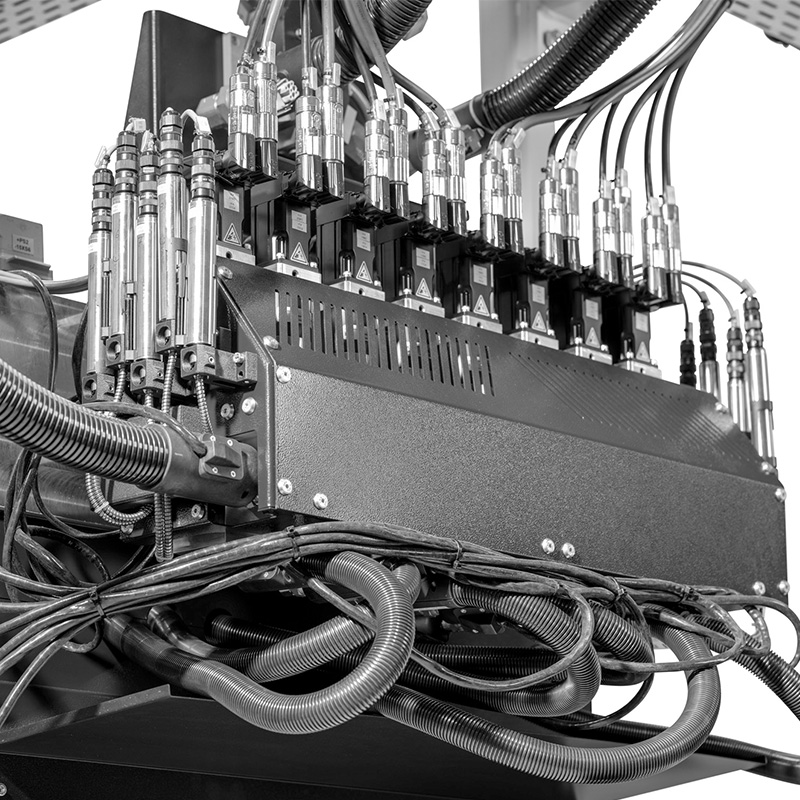

Pump station

Production of multi-layer non-wovens by means of thread or strip application

Contactless curtain coating nozzles enable precise strip or thread application for the production of multi-layer non-wovens with high permeability (low differential pressure) and with only a few grams of adhesive per square metre.

Coated web material

Efficient filter bonding using bead application with hot melt technology

For filter bonding – and especially for processing polyamide hot melt adhesives – bead application with single or double beads and a 2-hole nozzle is used. This technology enables processing temperatures of 210 to 240 °C for the precise and efficient bonding of filters, using high-temperature-resistant components.

Advantages of bead application technology for filter bonding:

GY0211 Extruder with pump station at the extruder outlet

KF1110 Nozzle application head in high-temperature design, with front-closing module for minimal stringing, prevents adhesive dripping, head body flow-optimised

Filter bonding: Equipment and systems

For filter bonding, we offer equipment and systems with precise, volume-accurate dosing systems, high repeat accuracy and a high degree of automation:

Have we got you interested?

You are looking for an individual and reliable filter bonding solution?

Phone us on +49 (0) 24 52 / 91 72-0 or email us at info@sm-klebetechnik.de – we will be happy to advise you!

About SM Klebetechnik

Our machines for hot melt processing and coating tasks are used successfully in the automotive, mechanical engineering, graphic arts and adhesive tape industries, as well as in the furniture, construction, wood and textile industries. Our units are also integrated into production systems at adhesive and sealant manufacturers and compounders. In our certified, owner-managed company, over 70 employees are committed to the needs of our customers every day.