Adhesive application systems from SM Klebetechnik

SM Klebetechnik is a medium-sized company specialising in the production and distribution of innovative adhesive application systems for industrial processing. With their different melting capabilities and application processes, our systems are used wherever adhesives need to be melted, conveyed, dosed and applied – e.g. in the automotive, textile, the wood and furniture industries, the paper/film sector and the construction industry, as well as for the production of filter, fleece and nonwoven articles and for filling and producing adhesives.

We offer you high-performance systems for the reliable application of EVA, PSA, PO, PA, PUR adhesives developed and built using state-of-the-art technology and innovative solutions. All adhesive application products from SM Klebetechnik are efficient, energy-saving and low-emission systems, enabling the gentle melting of hot-melt adhesives and efficient dosing.

Feel free to contact us at any time!

Feel free to contact us at any time!

SM Klebetechnik Vertriebs GmbH

Otto-Hahn-Str. 19a

D-52525 Heinsberg

Phone +49 (0) 24 52 / 91 72-0

Email: info@sm-klebetechnik.de

Adhesive application systems: range of standard equipment and special machinery

We offer our customers a wide range of standard equipment for the reliable application of high-viscosity sealants such as butyl or hybrid epoxies as well as bitumen for roof and building sealing using electric spindle drum melters and variable-slot nozzle technology. The engineers and experts at SM Klebetechnik also develop special machinery and complex adhesive application systems for optimum process integration. These include high-performance melters and applicators, application technology for contactless curtain coat adhesive application, sealless drum melters, special application heads with application widths of up to 2000 mm and other components.

SM Klebetechnik can provide you with all components for adhesive application systems – including melters, application heads, nozzles, hoses, distributors and air heaters.

We offer sealless melting systems, nozzle technology of up to 2000 mm, co-extrusion nozzles and adhesive-saving surface spray heads with low air consumption.

Here you can gain an insight into our portfolio together with a selection of our adhesive application systems and equipment:

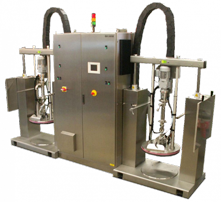

Drum melters for adhesive, bitumen and butyl application

Melting devices such as GX drum melters (20L, 200L) as single, tandem, 4-fold or 8-fold systems, GR bag melters (2L, 20 L), GW bag presses (without a pump), GS/GP tank devices (7 L, 10 L, 20 L, 25 L, 45 L, 65 L, 80 L, 100 L) and GY extruders, e.g. for applying hot melt adhesives.

For processing hot melt adhesives

For processing high-viscosity adhesives (butyl/bitumen)

For cable compounds, greases, lubricants

Adhesive melters and PUR bag melters

For processing non-reactive adhesives

For processing high-melting adhesives

For processing reactive adhesives

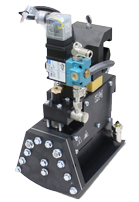

Application heads for hotmelts for surface, spray and bead application

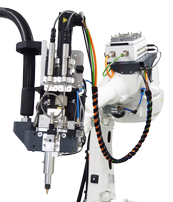

Our range includes KN/KF application heads for bead or spray application, KP pump application heads for bead, spray or combined application and KC CoEx and curtain coat application heads, e.g. for bead application.

For bead application

For spray application

For surface application

For robotic application

For special application

Machine technology for bitumen processing

We offer a wide range of equipment and systems for professional bitumen coating using various bitumen membranes (bitumen, polymer bitumen and screed membranes as well as bitumen sealing tapes) – from wide-slot nozzles and application heads to coating systems and modules.

Special machinery

Do you need customised solutions involving complex special machinery? At SM Klebetechnik, our experts develop customised machines for you – e.g. high-performance melters, applicators and heads as well as coating systems and other components that can be integrated perfectly in your processes. If you wish, we can even test the production process on your premises.

SM Klebetechnik also supplies hot melt hoses such as SD, SH, SA, SI, SJ, SN in various lengths with different glue cores, diameters, insulation and connections as well as heated glue distributors, heated ball track distributors and adjustable spray air heaters.

What factors influence the choice of the right system?

The appropriate adhesive application system depends on the container type (drums 20 L/200 L, slugs 200 g/2 kg, bags, granules), the desired melting rate in kg/h, the dosing accuracy, the desired application method (contactless or in contact, surface application e.g. roll goods or individual component bonding using spray or bead application) as well as the application speeds m/min, application lengths in mm and the number and length of interruptions for intermittent applications.

Systems for adhesive application – low-maintenance and reliable

Our adhesive application systems for industrial use require little maintenance thanks to their modular design. As a rule, only the filters and switching modules of our adhesive application systems and application heads need maintenance. Parts subject to wear, switching valves and seals on our adhesive application systems can be easily replaced.

Adhesive application systems from SM Klebetechnik – advantages at a glance

Would you like to find out more or test our adhesive application systems in practice with your preferred adhesives or sealants?

Call us on +49 (0) 24 52/91 72-0 or write to us at info@sm-klebetechnik.de – we’ll be happy to help you!