Application heads for hotmelts

Application heads for hotmelts

Individual solutions for your application systems

Individual solutions for your application systems

Assemble your application system in accordance with your individual requirements. In order to use our devices flexibly, you can add modules to the SM Klebetechnik application heads for hotmelt adhesives or swap them for other models.

Feel free to contact us at any time!

Feel free to contact us at any time!

SM Klebetechnik Vertriebs GmbH

Otto-Hahn-Str. 19a

D-52525 Heinsberg

Phone +49 (0) 24 52 / 91 72-0

Email: info@sm-klebetechnik.de

We offer you system application heads for

We offer you system application heads for

Bead application

Bead application

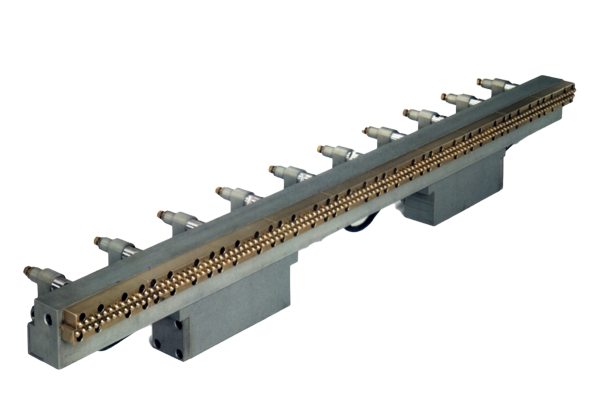

MULTILINE – KL1000

MULTILINE – KL1000

Multiline application head for non-contact application of the finest traces of hot melt adhesive in continuous operations, can be used for breathable bonding in the filter, fleece and textile industry or for joining flexible material webs.

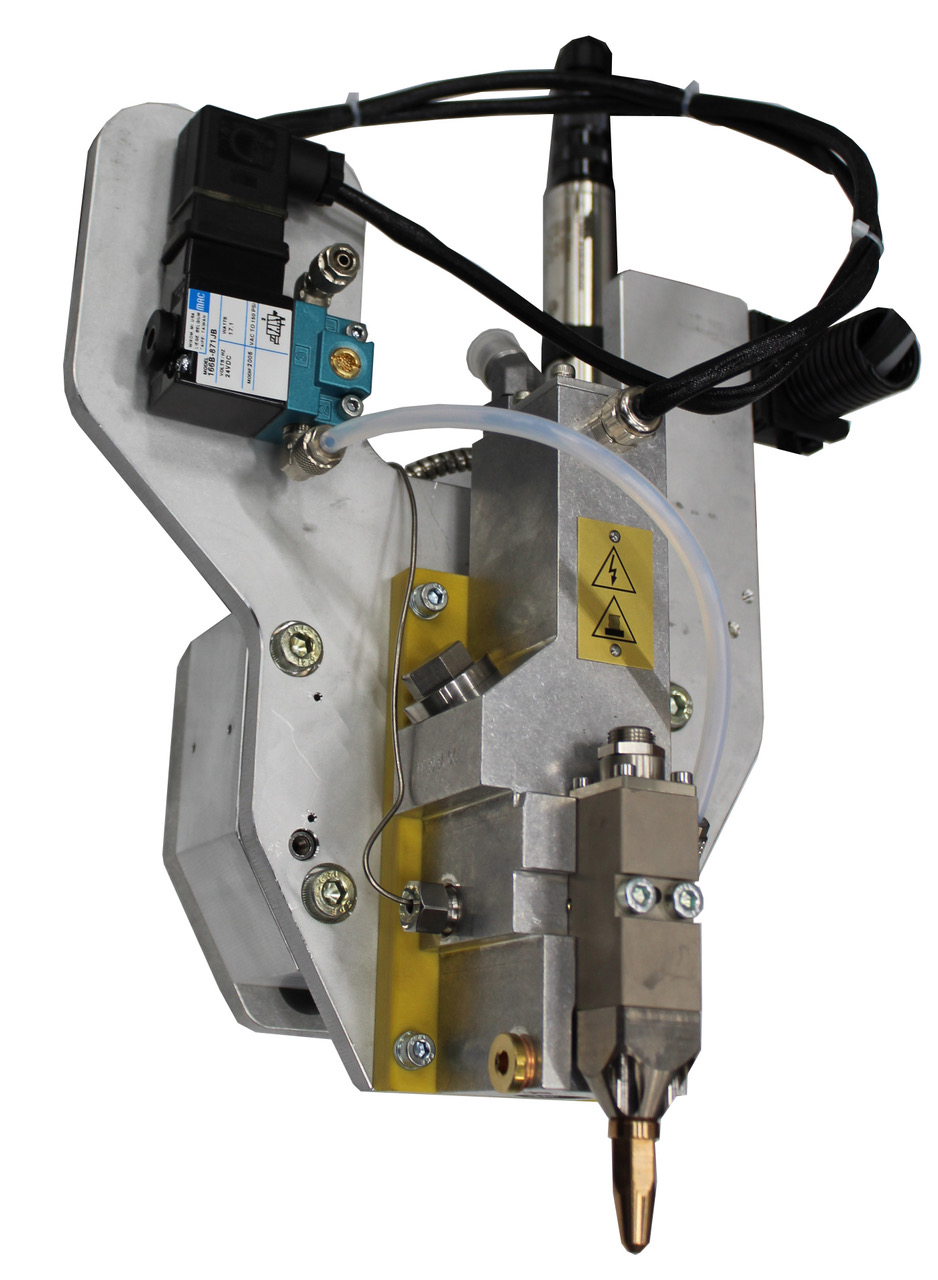

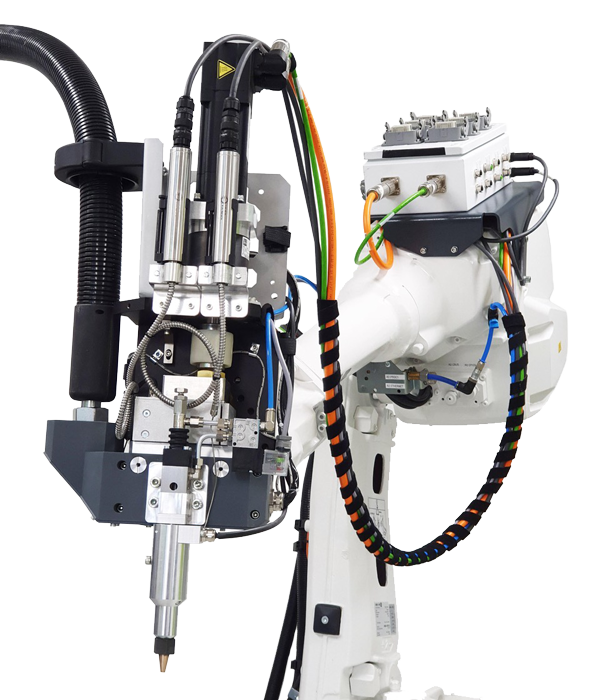

ROBOTIC APPLICATION – KN53

ROBOTIC APPLICATION – KN53

Robust and modular electrically heated application heads, with electro-pneumatic controls and very fast switching speeds for the application of intermittent hot glue beads.

Spray application

Spray application

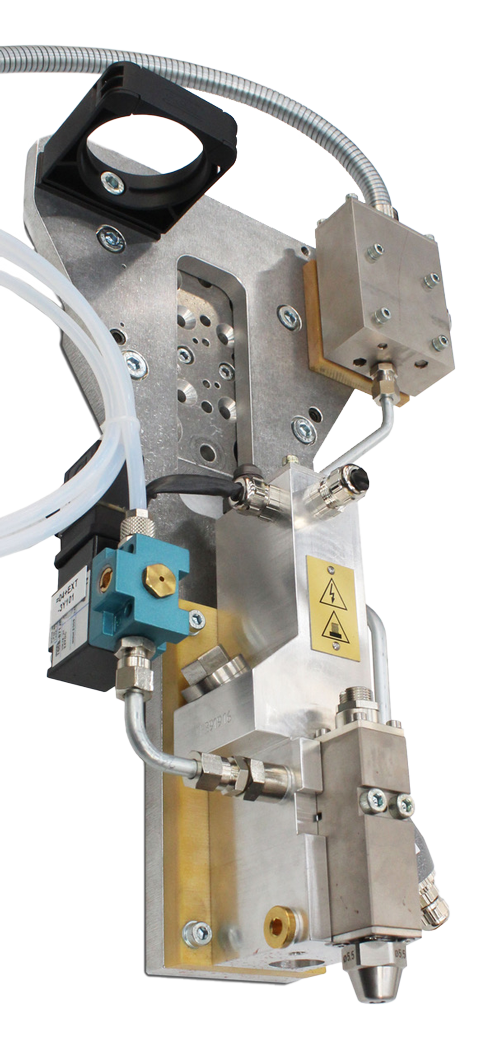

DEFLECTOR APPLICATION – KN51

DEFLECTOR APPLICATION – KN51

Robust and modular electrically heated application heads, with electro-pneumatic controls and very fast switching speeds for non-contact spray applications.

FIBRE SPRAY – KF0170

FIBRE SPRAY – KF0170

Application head for large-area spraying with an application width of 200mm for cost-optimised bonding of web goods and moulded parts.

Area application

Area application

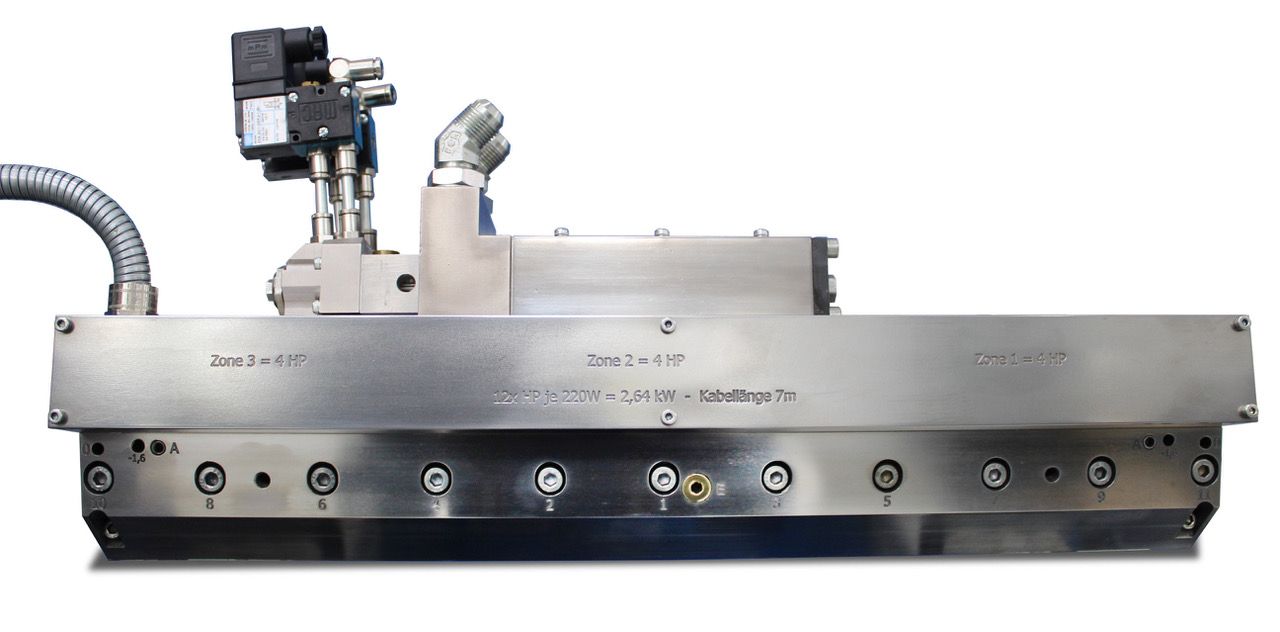

SLOT NOZZLES – KV3

SLOT NOZZLES – KV3

Surface application head with manually or servo adjustable application width for precise thermoplastic hotmelt adhesive/sealant application in web contact transfer or for the contactless curtain coating with a width of up to 1200 mm.

COEX – KC05

COEX – KC05

Heated application head for non-contact co-extrusion coatings, for special multi-layer composites with 2 different thermoplastic hotmelts for simultaneous processing in precise continuous operations.

Robotic application

Robotic application

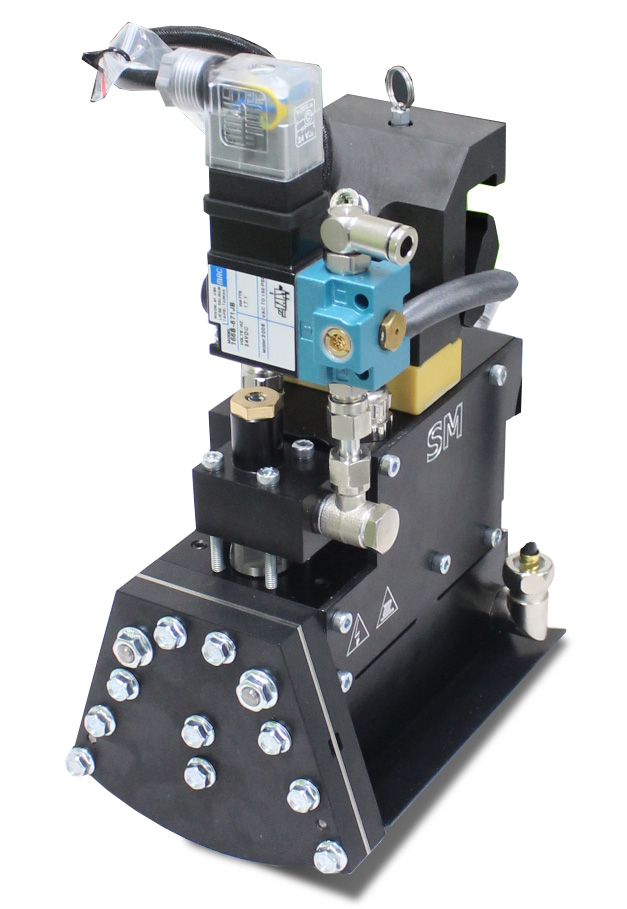

BEAD APPLICATION – KP81

BEAD APPLICATION – KP81

Servo pump application head for the precise and synchronised application of material beads in intermittent or continuous operations in connection with a melting system and a robotic automation unit.

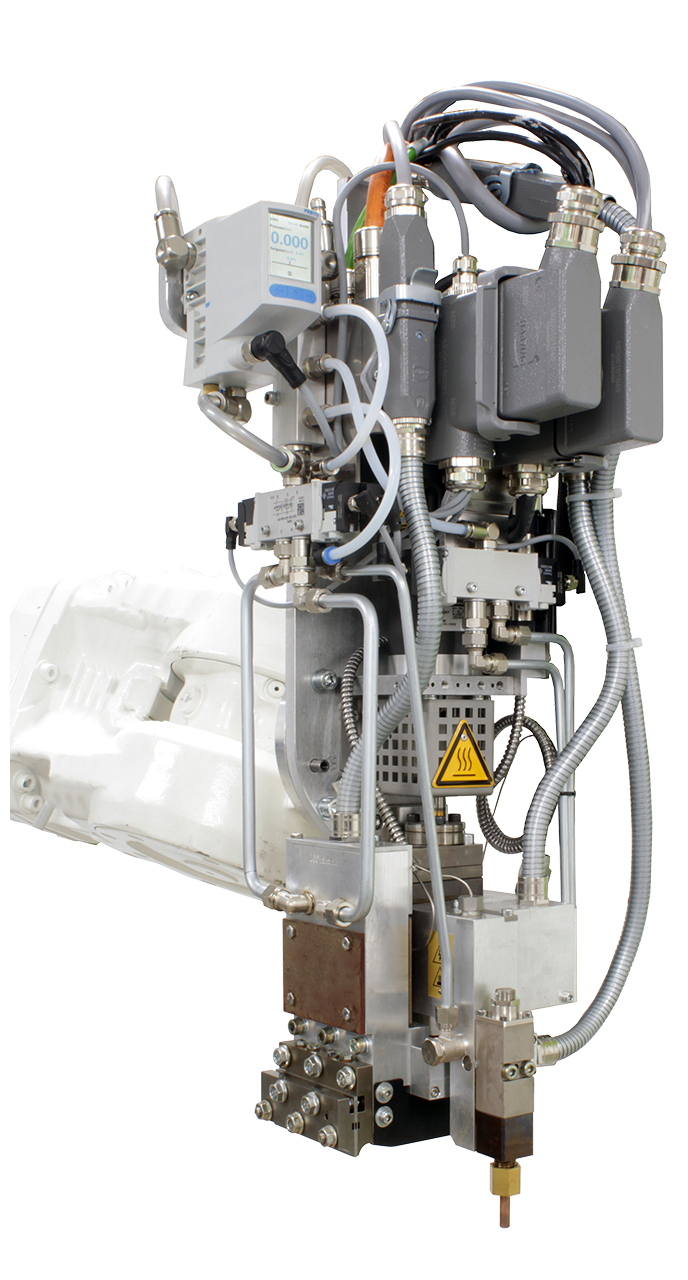

BEAD AND SPRAY APPLICATION – KP43

BEAD AND SPRAY APPLICATION – KP43

Heated, rheologically optimised application head with a precision servo-driven gear pump, for high-precision spray and bead application of thermoplastic or reactive adhesives and sealants in robotic mode.

Special application heads

Special application heads

HAND GUNS (KG11+KG21)

HAND GUNS (KG11+KG21)

Radio-controlled hand guns, 360° rotatable, for manual bead or spray application of hot melt adhesives.

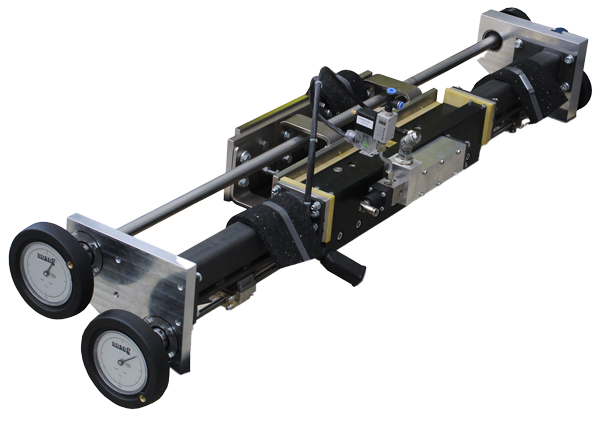

HAND-GUIDED APPLICATION HEADS – KG31

HAND-GUIDED APPLICATION HEADS – KG31

Hand-guided application head for manual bead application of hot melt adhesives